1.The double-head cutting saw is a profile cutting tool used in the production of doors and windows. It is suitable for cutting aluminum and plastic profiles. The transmission and feed of the sawing machine are controlled by a numerical control system. The cutting size has high precision, simple operation, reliable performance, and advanced technology. The cutter adopts cemented carbide circular saw, which has fast cutting speed and high production efficiency. It is an ideal equipment for the mass production of aluminum doors and windows.

2.The double-head saw is suitable for cutting aluminum doors and windows and aluminum curtain wall profiles. It adopts linear guides with high precision and good stability. It can achieve 45°, 90° angle cutting. The two saw heads can cut at the same time or separately. It is hard The alloy saw blade has high processing precision and high durability. The protective cover automatically opens and closes to make work convenient.

3.The main purpose and scope of application is to adapt to the development of aluminum and plastic doors and windows processing industry, and developed a new model, the machine is simple to operate, reliable performance, advanced technology, easy to maintain, the machine is mainly used for the processing of plastic and aluminum profiles . The tool uses carbide saw blades, which have high cutting speed, high efficiency and high machining accuracy. The two saw heads of this machine can work independently or at the same time. When working at the same time, it can cut the required length and the angle of the two ends of the profile at one time.

]]>Aluminum profile cutting saw is the main machinery for processing aluminum doors and windows. The processing of aluminum doors and windows begins with profile cutting. In the entire aluminum door and window processing process, profile cutting is one of the more important processing procedures. The cutting precision of the profile will directly affect the angle accuracy and strength of the aluminum doors and windows, and then the dimensional accuracy and angle accuracy of the finished aluminum doors and windows. So how should you choose an aluminum profile cutting saw?

- Look at the appearance, see whether the frame is solid and whether the appearance details of the aluminum profile cutting saw are handled properly.

- look at the inside, have a deep understanding of its internal performance, functional characteristics, and make choices based on your own needs.

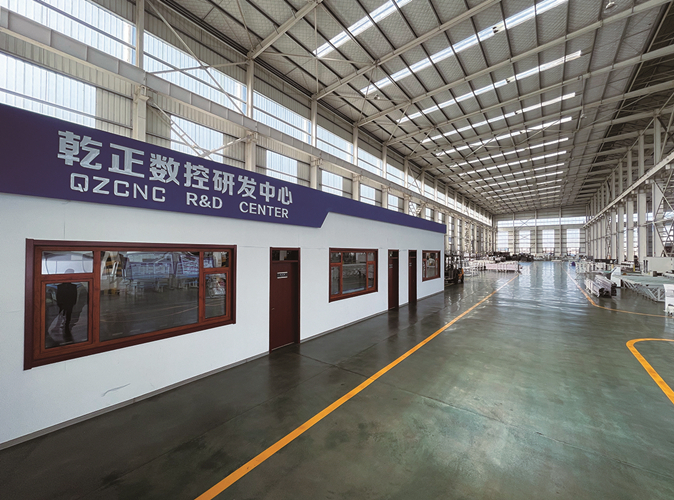

- Looking at processing, good equipment depends on assembly. Companies with a long time to build factories often have a group of experienced and skilled assembly technicians. With years of accumulation, they can bring the performance of aluminum profile cutting saws into full play. good.

4.Looking at the company’s strength, some people may think that with the above three points, it doesn’t matter, this is actually one-sided. Powerful companies have complete pre-sales, in-sales, and after-sales systems and brand awareness. Choosing a reliable brand can largely avoid the phenomenon of small workshop management that does not focus on brands and blindly pursue sales.

We know that aluminum profiles are long strips, generally 6 meters long, and need to be sawed according to the actual size of use. So what should we pay attention to when cutting aluminum profiles?

Youtube:https://www.youtube.com/watch?v=CPPIL3h8-os

- Choose a professional saw blade, because the hardness of industrial aluminum profile is not as big as that of steel, it is relatively easy to saw, but because the hardness is not large enough, it is easy to stick to aluminum, so the blade must be sharp, and it must be replaced after a period of use.

- Choose a suitable lubricant. If you do not use lubricant for dry cutting, the cut surface of the aluminum profile will have a lot of burrs, which is difficult to clean and will damage the saw blade.

- Most aluminum profiles are cut at right angles, and some require bevel cuts, 45 angles are more common. When cutting the bevel, the angle must be controlled well, and it is best to use a CNC sawing machine to saw.

Let’s take a look at what steps need to be cut after industrial aluminum extrusion is produced?

- The aluminum profile must be sawed after extrusion. At this time, it is rough cut. The length is generally controlled at 6 meters or more and 7 meters or less. Too long industrial aluminum profiles are inconvenient to enter the aging furnace for aging and oxidation in the oxidation tank.

- If the customer buys the material and goes back to sawing and processing, we need to saw off the oxidation electrodes at both ends after the anodized packaging is finished. The length of the profile is generally controlled at 6.02 meters.

- If you purchase semi-finished products for processing, we have to transfer to the processing workshop to perform fine cutting according to the actual size used. The size tolerance of fine cutting is generally controlled within ±0.2mm. If there is a need for further processing, further processing (punching, tapping, milling, etc.) is required.

Double-head mitre saw: used for cutting profiles to make aluminium doors and windows, According to the size of the aluminium doors and windows, cut the main profile at the required angle. The main angles are 90° and 45°. JMD has two types of double-head saws, CNC double-head saw and digital display double-head saw.

(1) CNC double head saw features:

1.Schneider CNC system & automatic profile supporting system.

- Driven by rack, the right machine head horizontally moves with precise repeat orientation,The repetitive positioning accuracy can reach 0.02mm.

- Available to input a series of data (cutting length & quantity) to realize the continuous cutting.

(2) Digital display double-head saw features:

- Spindle motor(for driving saw blade) made by professional manufacturer

- Saw blade: Diamond ZhiGuang; Cable & electric wires: YiChu; Pneumatic components: AirTAC

- Saw blade feeding driven by hydraulic damping cylinder through HIWIN linear guide rail pair

- Pneumatic profile supporting system & pneumatic right machine head lock system

Cutting length digital displayed.

Single-head saws are also called hand saws: they are mainly used for cutting small-sized materials such as buckles and locks.

Corner connector cutting machine: Combine the main profiles that have been cut at 45° through angle codes. Jmd has two type of corner connector cutting saw.

(1) CNC corner connector cutting saw features:

1.This machine is mainly used for cutting aluminum corner profiles of broken bridge doors and windows, and can also be used for 90 °cutting of some industrial aluminum profiles.

2.Broken bridge aluminum doors and windows enterprises must have a new type of CNC cutting equipment.

3.The machine has the advantages of simple operation, reliable performance, advanced technology, and easy maintenance and maintenance.

(2) Auto Corner Connector Cutting saw features:

- Cable & electric wires: ShangHai YiChu; Pneumatic components: AirTAC; Saw blade: Janpan DaHe

- Profile feeding & saw blade feeding both driven by air-liquid damping cylinder

- Cutting quantity digital displayed

- Machine spindle made by professional manufacturer.

- Machine body is overall structure with good rigidity.

Aluminum window and door equipment includes many, cutting saws, angle machines, milling machines and so on.

The double-end cutting saw of heat-insulated aluminum window and door mainly includes numerical control precision cutting saw, digital display precision cutting sawing machine, precision cutting sawing machine and ordinary double-end cutting sawing machine.

Among them, CNC precision cutting sawing machine has the advantages of high processing speed, high efficiency and high precision.

The processing effect of digital display precision cutting sawing machine is the same as that of precision cutting sawing machine, except that the former has digital display function, so people can use digital display meter to determine the length more conveniently, quickly and accurately, and improve the efficiency of door and window processing.

Both of them are very suitable for medium-scale projects of thermal insulation broken bridge aluminum window and door equipment.

As for the ordinary double-head cutting sawing machine, that is, what we usually call “saw king” or “06 saw”, it is the earliest research and development and use, and it is also a relatively simple window and door equipment.

For customers with an annual output of less than 10,000 square meters, this double-ended saw is the best choice for you to buy broken bridge aluminum window and door equipment.

Compared with the previous 06 saw, the current saw machine adds a special solenoid valve for spray, which enhances the lubrication function of the equipment and prolongs the service life of the saw blade.