Aluminum window frames are widely used in the construction industry, with the advantages of lightweight, durable, beautiful and so on. This article will introduce the manufacturing process of aluminum window frame in detail.

1. Prepare raw materials

The main raw material of aluminum window frame is aluminum. Aluminum profiles are usually made of aluminum alloys, which contain elements such as aluminum, copper, and magnesium. These elements can improve the physical and chemical properties of aluminum, giving it better corrosion resistance, strength and plasticity.

2. Cut and punch

Extruded aluminum profiles need to be cut and punched to get the desired size and shape. This process is usually done using a CNC machine that allows precise control of the size and position of the cut and punch.

3. Assemble

Aluminum window frames are usually assembled using screws or rivets to join the aluminum profiles together. During the assembly process, it is necessary to ensure that the connection between the aluminum profiles is tight to prevent water leakage or air leakage.

4.Quality inspection

In the manufacturing process, the quality of the aluminum window frame needs to be inspected to ensure that its size, shape, surface treatment and so on meet the requirements. Common inspection methods include dimensional measurement, appearance inspection and corrosion resistance test.

Together, these steps guarantee the quality and performance of aluminum window frames, making them a widely used material in the construction industry.

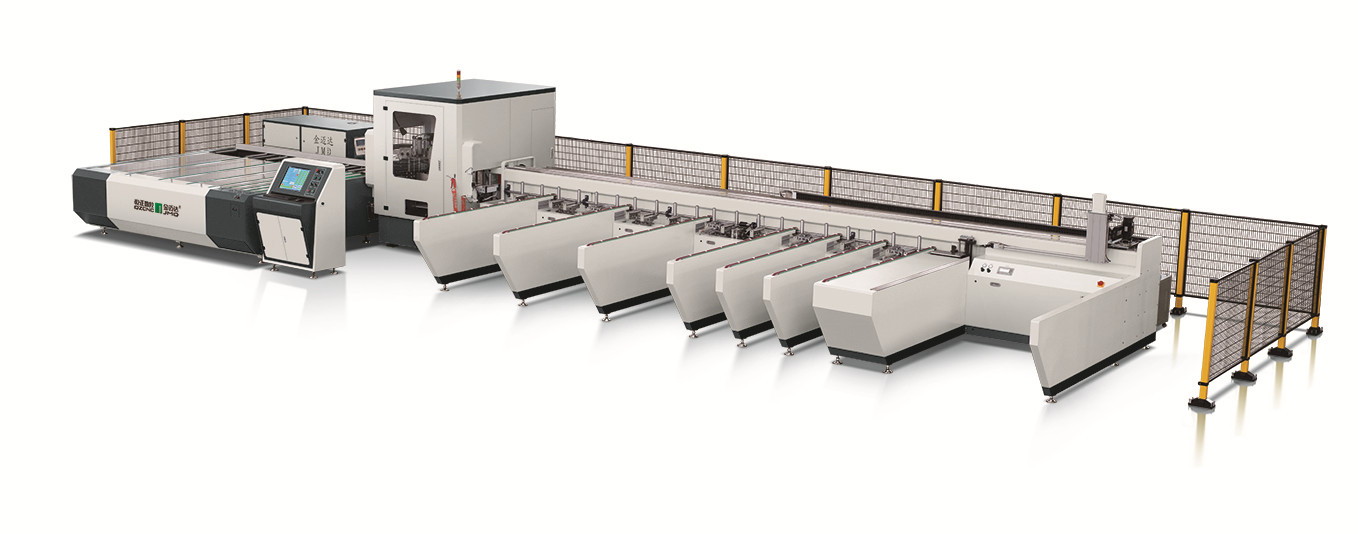

Aluminium Window Production Line, Aluminium Window Fabrication Machinery

Aluminium Window Production Line is the highly technological solution for the production of door and window frames. It combines superior versatility and high production levels thanks to the total integration of various machines. System lines perform all the operations of planing, tenoning, drilling-routing and profiling thus completing the work-pieces in all their parts.

]]>At present, aluminum doors and windows are very popular in the selection of home decoration products. First, because aluminum is very light, it is the best choice for frame doors and windows; second, aluminum can be customized and matched according to specific requirements.

1. Energy saving and environmental protection. Aluminum profiles have superior corrosion resistance and high strength-to-weight ratio, making them the best choice for door and window materials. Compared with the use and loss of doors and windows of other materials, aluminum alloy doors and windows have a long service life and are also the correct choice for family cost investment.

2. Sturdy and durable.Aluminum profiles are very strong and can be processed into different sizes and shapes.After surface treatment, aluminum profiles of different colors can be obtained, which are more suitable for different home improvement styles.Unique doors and windows can be designed according to the different hobbies and aesthetic views of the owners.

3. High recovery rate.Aluminum sliding windows can be recycled and reused, which is an energy-saving material.Aluminum doors and windows do not rust, fade, or fall off, and require almost no maintenance. Spare parts have a very long service life and save maintenance costs.

]]>