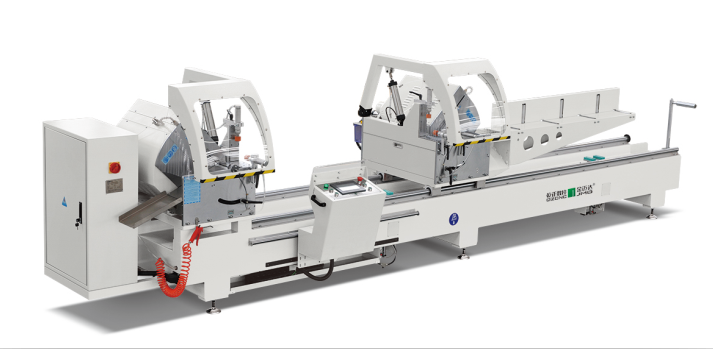

Thermal break aluminum doors and windows machine is mainly for processing thermal break aluminum profiles. A set of thermal break aluminum doors and windows machine includes aluminum cutting machine, corner crimping machine, milling machine, punching machine etc. So what are the precautions when using these machines?

Before using the thermal break aluminum door and window machine to work normally, the problems that need to be paid attention to are:

- Electricity. The conventional power supply voltage of the machine is 380V. So everyone must pay attention to the connection between the live wire and the neutral wire when wiring. Generally, the color of the live wire is black or blue, and the neutral wire is red (each factory depends on its own situation). You can switch the two ends at any time.

2. Air source. Since the profiles of door and window machine are compressed by cylinders, it is necessary to ensure sufficient air supply. If the air pressure is not reached, the entry and exit of the saw blade of the aluminum profile cutting saw will be affected, and the processing effect will also be affected accordingly. The working pressure range of general machine is 0.5~0.8Mpa.

- Equipment, mainly adjust the cutting machine.

(1) First adjust the position of the side pressing cylinder. Place the profile to be processed on the work surface, then adjust the press head of the equipment to the middle of the profile, and then lock the cylinder support plate.

(2) Then adjust the speed of the saw blade. During the operation of the machine, if it is found that the feeding speed of the saw blade is too fast or too slow, the feeding speed can be adjusted by adjusting the speed regulating valve on the feeding cylinder.

First of all, the failure analysis of aluminum cutting machine problems:

- Vibration problem: Some aluminum cutting machines are hung with abrasive belts. After starting the machine, the machine vibrates a lot. If it is not fixed, it will “run around”! What is the reason? The main reason is that the balance of the rotating wheel is not good! The rotating wheel has a rubber wheel, a guide wheel, and a motor pulley. One of the three rotating wheels has poor accuracy, poor balance, and poor machine jitter! Another reason is that the fitting clearance of the parts of the support wheel is too large, causing relative movement between the parts and vibration. Then, the motor is not fixed, and it also vibrates.

- Noise problem: The noise is mainly due to insufficient rigidity of the base and supporting parts, and excessive clearance of matching parts (some factories have poor and backward processing equipment, coupled with poor quality awareness, the manufactured parts are very bad, and there is almost no matching tolerance requirements!), the selection of inferior bearings, the speed of the abrasive belt is too fast, etc.

- Life problems: some aluminum cutting machines are broken after a short time. There are several reasons: gray cast iron is used for the adjustment part, 45# carbon steel is not used for precision casting, or heat treatment is not carried out, the bearing quality is not good, and the lubrication Not good, the spindle has not undergone modulation heat treatment, or the hardness of the treatment is too low or too high (too low and easy to wear, too high to break), and the motor quality is not good.

- Problems in use: the size and structure of the machine are very important. Better structure and scientific size are the key to the efficiency of polishing workers.