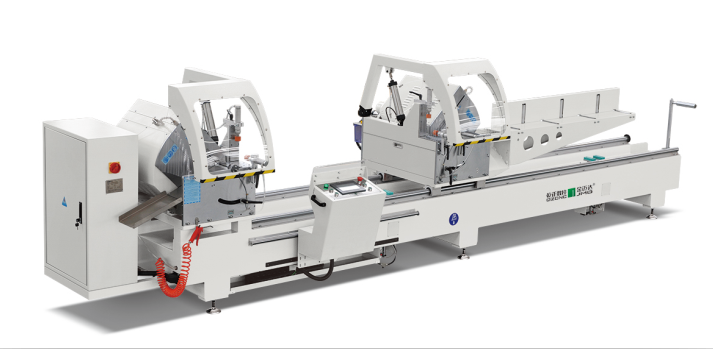

Thermal break aluminum doors and windows machine is mainly for processing thermal break aluminum profiles. A set of thermal break aluminum doors and windows machine includes aluminum cutting machine, corner crimping machine, milling machine, punching machine etc. So what are the precautions when using these machines?

Before using the thermal break aluminum door and window machine to work normally, the problems that need to be paid attention to are:

- Electricity. The conventional power supply voltage of the machine is 380V. So everyone must pay attention to the connection between the live wire and the neutral wire when wiring. Generally, the color of the live wire is black or blue, and the neutral wire is red (each factory depends on its own situation). You can switch the two ends at any time.

2. Air source. Since the profiles of door and window machine are compressed by cylinders, it is necessary to ensure sufficient air supply. If the air pressure is not reached, the entry and exit of the saw blade of the aluminum profile cutting saw will be affected, and the processing effect will also be affected accordingly. The working pressure range of general machine is 0.5~0.8Mpa.

- Equipment, mainly adjust the cutting machine.

(1) First adjust the position of the side pressing cylinder. Place the profile to be processed on the work surface, then adjust the press head of the equipment to the middle of the profile, and then lock the cylinder support plate.

(2) Then adjust the speed of the saw blade. During the operation of the machine, if it is found that the feeding speed of the saw blade is too fast or too slow, the feeding speed can be adjusted by adjusting the speed regulating valve on the feeding cylinder.

Aluminum windows are more and more popular in today’s world. If I want to start the business of it, what should I do?

First, we need to confirm what kind of windows to make, sliding windows, casement windows or swing windows? Then to find the aluminum profile supplier.

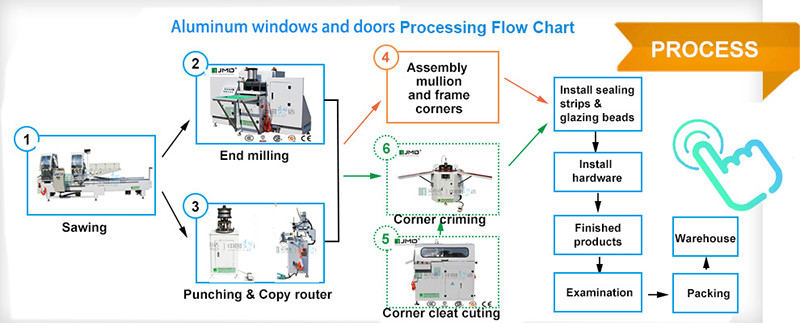

Second, find the right window machines which suitable for the profiles. As there’s no universal machines can make all kinds of windows, we have to make sure the machines are available for the profiles, that’s why we need to confirm the profile supplier first. If we want to make thermal break casement windows, basically, we’ll need double miter saw, corner crimping machine, end milling machine, copy router/CNC milling machine, punching machine and corner connector saw, etc.

Before buy the machines, we’d better send some aluminum samples to the machine suppliers to confirm they machines can process the profiles. Don’t forget to order enough wearing parts for the machines such as saw blades, milling cutter and crimping knives, etc. As the window machines need to work with compressed air and electricity, you also need to buy an air compressor, air tank, air hose and cables, etc.

Besides of the big window machines, we also need to buy some small tools such as meter stick, protractor, vernier caliper, gradienter, pencil, electric drills and chop saw, etc.

Then, we need to find supplier of glasses, sealants, hardware and rubber strips, etc.

To make aluminum windows is not a easy job, you also need some other tools or materials,but if you get all the items mentioned above, you can start the job. Good luck!

]]>In the door & window machine industry for 23 years,it is found that the customers you encounter usually have a habit:

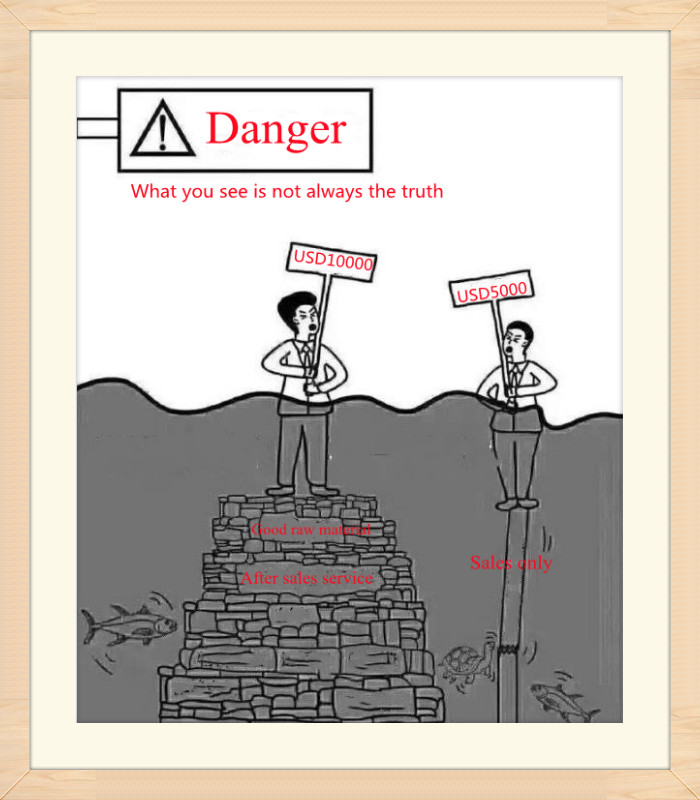

Likes to negotiate prices with high-end devices,talking about quality with low-end devices.

Customers will say: The CNC double-head cutting saw from another brand in China is exactly the same as yours, why is yours so expensive? please see below,can this be the same?

As the saying goes,”dilettante watch the scene of bustle, experts see road”. For example,for a aluminium CNC double head cutting saw,What you see is a similar look and cutting method. Do you really know the internal structure of the device?

First of all, the body is the basis and premise to achieve machining stability What kind of aluminum is used for the body?

Are body bevels handled and cleaned up to standard before welding?

Are preheating temperatures and inter layer temperatures properly controlled?

Does the soaking and drying of the body after welding meet the requirements?

Secondly, the choice of parts and operating system is the soul of cutting Precision. JMD aluminum profile cutting operating system, servo motor and all electrical parts are using Famous brand from domestic and overseas Effectively ensure the coordinated operation of all electrical components Thus greatly improve the cutting precision, surface flatness and cutting efficiency.

Lastly, the company’s after-sales service system. After-sales service is not the same as only dealing with unexpected problems of equipment. JMD after-sales service system is including plant layout, doors and Windows production process diagram, training engineering and technical personnel, software technology training as well as equipment installation and commissioning, on-site production guidance, until the production of qualified products and other whole process services.

So when you actually have the patience to compare two devices that you think are “identical” ,do you still ask the same question you wanted to ask?

Business is about honesty. Please believe that quality and price is always proportional to the truth!

Different machine is used in the production of doors and windows, so higher requirements are also placed on the operators of window machinery. During the use of some window machine, hidden faults often occur, resulting in interruption of production activities, which requires Regular maintenance and repair of machinery and machine can play a preventive role and ensure efficient production efficiency. If the mechanical machine is not maintained and maintained for a long time, it will cause the wear and tear of the parts. Once the failure occurs in the production, the losses will be more serious.

Let’s talk about the maintenance of door and window machine below.

Lubrication of bed guides and working guides: use 40# mechanical oil or 46# anti-wear hydraulic oil in summer; use 30# mechanical oil or 32# anti-wear hydraulic oil in winter.

Adjustment of the air source processor (oil-water separator, pressure reducing valve, lubricator): the oil-water separator is a differential pressure drainage type, and the compressed air should be closed after the machine is shut down to discharge the accumulated water; the pressure gauge is adjusted to 0.5~0.8 MPa; the lubricator ensures a certain oil level (mechanical oil 20#), and the oil volume is adjusted to about three drops per minute.

The machine should be kept clean, and the aluminum scraps should be cleaned in time after each shift; the dust on the guide rail and the surface of the machine tool should be wiped off, and the exposed surface of the guide rail should be smeared with grease to prevent rust.

Clean the aluminum chips and dirt inside the machine head once a month (the cover needs to be removed). In particular, the work-in linear guides should be wiped clean, and lubricated and moved back and forth several times to observe whether there is a stuck phenomenon, and if there are any problems, they should be solved in time.

When the machine is used for the first time and after being placed for a long time, it should be carefully checked before running.

For the cooling and lubrication of the milling cutter, we first recommend using kerosene; secondly, special cutting fluid for aluminum profiles without water can be used.

We strongly advise against the use of emulsified oils and water-based cutting fluids.

Common faults and solutions

After the first use or after the device is reconnected to the power supply, if the operating device does not work, first check whether the power supply has electricity; then check whether the phase sequence protection relay indicator light in the device distribution box is lit. If not, please exchange any two-phase live wire of the power cord.

The pressure reducing valve cannot reach the working pressure: first check the output pressure of the air compressor. If the output pressure of the compressor reaches, then check whether the pressure regulating valve spring is broken or whether the pipeline is leaking. If there is any problem, repair or replace it in time.

If the lubricator does not drip oil during operation, check the oil quantity of the oil cup, or check whether the oil needle hole of the lubricator is blocked, and repair or replace it if there is any problem.

Electrical or pneumatic system failure: refer to the electrical schematic diagram and the gas circuit schematic diagram, and professionals can take professional methods to analyze, find and eliminate, or directly contact the machine manufacturer.

Edited by JMD

First of all, the failure analysis of aluminum cutting machine problems:

- Vibration problem: Some aluminum cutting machines are hung with abrasive belts. After starting the machine, the machine vibrates a lot. If it is not fixed, it will “run around”! What is the reason? The main reason is that the balance of the rotating wheel is not good! The rotating wheel has a rubber wheel, a guide wheel, and a motor pulley. One of the three rotating wheels has poor accuracy, poor balance, and poor machine jitter! Another reason is that the fitting clearance of the parts of the support wheel is too large, causing relative movement between the parts and vibration. Then, the motor is not fixed, and it also vibrates.

- Noise problem: The noise is mainly due to insufficient rigidity of the base and supporting parts, and excessive clearance of matching parts (some factories have poor and backward processing equipment, coupled with poor quality awareness, the manufactured parts are very bad, and there is almost no matching tolerance requirements!), the selection of inferior bearings, the speed of the abrasive belt is too fast, etc.

- Life problems: some aluminum cutting machines are broken after a short time. There are several reasons: gray cast iron is used for the adjustment part, 45# carbon steel is not used for precision casting, or heat treatment is not carried out, the bearing quality is not good, and the lubrication Not good, the spindle has not undergone modulation heat treatment, or the hardness of the treatment is too low or too high (too low and easy to wear, too high to break), and the motor quality is not good.

- Problems in use: the size and structure of the machine are very important. Better structure and scientific size are the key to the efficiency of polishing workers.

The quality of aluminum door and window machinery can be roughly judged from the selection of raw materials, the quality of aluminum surface treatment and internal processing, and the price of aluminum door and window machinery.

1.From the point of view of materials, the thickness, strength and oxide film of high-quality aluminum door and window machinery should meet relevant standards. The wall thickness should be greater than 1.2 mm, the tensile strength should reach 157 Newtons per square millimeter, the yield strength should reach 108 Newtons per square millimeter, and the oxide film thickness should reach 10 microns. If it does not meet the above standards, it is a low-quality aluminum alloy door and window equipment and cannot be used.

2.Look at processing. High-quality aluminum alloy door and window equipment, fine processing, exquisite installation, good sealing performance, and convenient opening and closing. Inferior aluminum door and window machinery blindly choose aluminum profiles and specifications, rough processing, sawing instead of milling, not installed as required, poor sealing performance, difficult to open and close, not only leaking wind and rain, cracking the glass, but also when encountering strong winds and external forces , It is easy to scratch or knock off the sliding parts or glass, and damage things.

3.Look at the price. Under normal circumstances, due to high production costs, the price of high-quality aluminum door and window machinery is about 30% higher than that of inferior aluminum door and window machinery. The tensile strength and yield strength of some aluminum alloy doors and windows made of aluminum profiles with a wall thickness of only 0.6-0.8mm are far lower than the relevant standards and are unsafe to use. In addition, there are currently many self-employed individuals who process aluminum alloy doors and windows and do not understand the structural characteristics and performance of aluminum alloy doors and windows.

4.The current standard profile thickness is 1.4mm. If the supplier chooses a material with a wall thickness of 1.2mm or 1.0mm or even thinner, it is an unqualified product. Please pay attention when buying.

]]>