Thermal break aluminum window Jamb have mainly three processes: 45 °cutting,milling holes(glue injection hole, pin hole, mullion connection hole, water drainage, mounting hole ), corner crimping

JMD recommend two type of machines for 45 ° cutting function& milling holes function

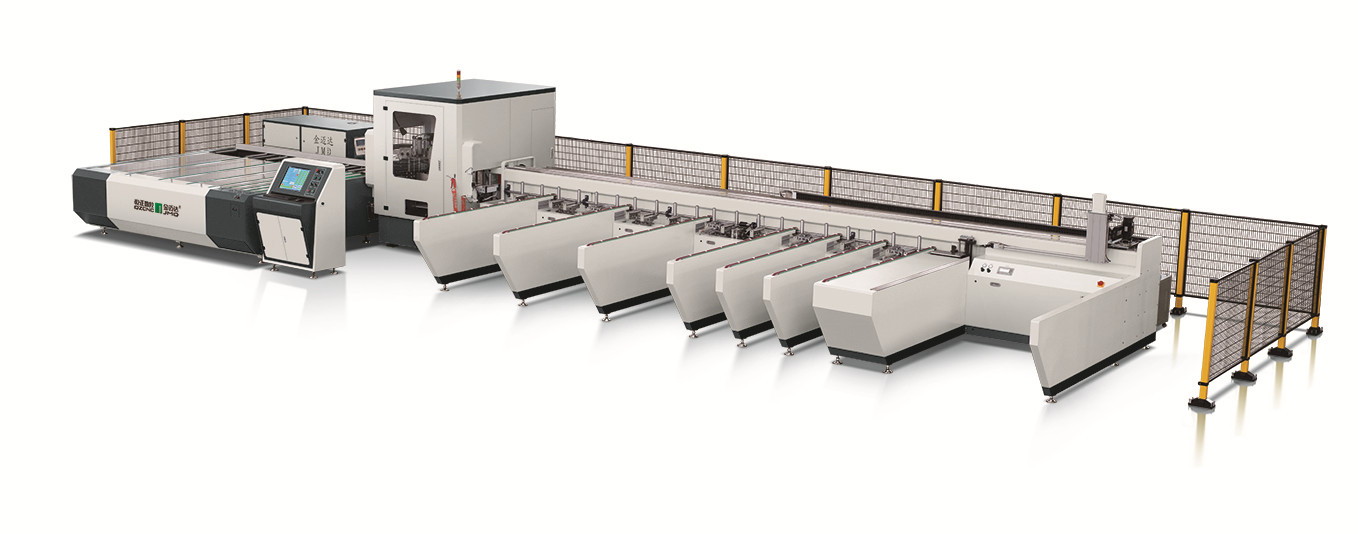

No.1 Frame production line (LJCKB-6500)with production capacity 800m2 /day

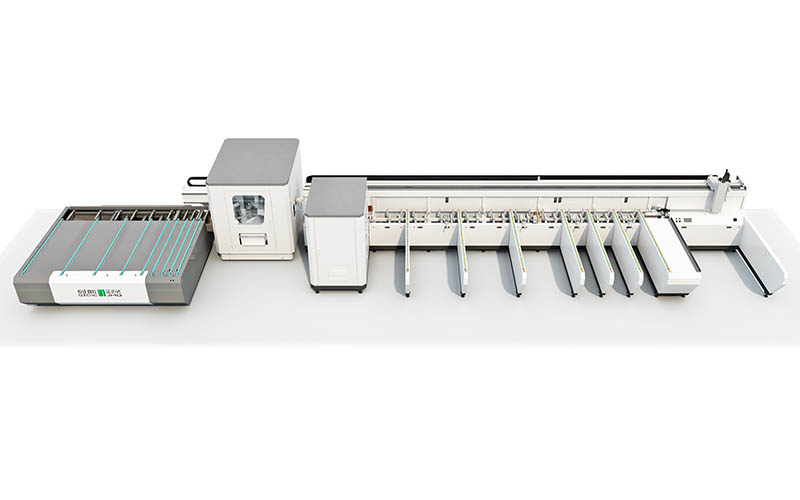

No.2 CNC Machining Center(LJZX4-6500) with production capacity 200m2 /day

JMD recommend Heavy duty Corner Crimping Machine(LJZJZ-150) for corner crimping function

]]>

The corner crimping machine is a special equipment for the production of high-grade broken bridge aluminum doors and windows, which is suitable for 90 degree angle connection of corner structure aluminum doors and windows. According to the different angles that can be assembled, it is divided into single-head corner crimping machine, double-head corner crimping machine, and four-head corner crimping machine.

Principle and structure:

- Main components

The corner crimping machine is composed of main parts such as body, worktable, positioning cylinder, riveting device, corner crimping cylinder, corner crimping slide, electric control panel, foot switch and so on. The pneumatic system consists of solenoid valves, pressure gauges, mist, water separators, etc. The hydraulic system is composed of hydraulic pump, solenoid valve, high pressure hose, hydraulic relay, etc. - Working principle

The corner crimping cylinder pushes the corner crimping slide, which moves forward, and simultaneously pushes the left and right riveting shafts. The corner crimping knives on the riveting shaft realize the 90-degree connection of aluminum doors and windows

- Structural features

This machine is a new model developed on the basis of absorbing the advantages of similar foreign products. This machine adopts pneumatic, electric, hydraulic and operation control. Due to the new mechanical linkage structure, the influence of oil pressure fluctuations on the quality of the group angle is eliminated, the group angle is completely synchronized, the group angle depth is more consistent, and the group angle is 90 degrees The angle is more accurate. In addition, the front and rear positioning adopts the up and down adjustable positioning device, and the front and rear distance adjustable positioning device is suitable for processing profiles with different cross-sectional shapes and sizes. - Installation

(1) Environment and requirements

The corner crimping machine should be installed on a dry, dust-free, and non-corrosive indoor hard cement floor.

(2) Out of the box in place

After unpacking, move the corner crimping machine together with the packaging base to the installation position, remove the fastening screws of the corner assembly base, and use the moving tool to move the corner crimping machine to the installation position.

(3) Ground

The frame of the corner crimping machine should be grounded. When grounding, use yellow and green double-color stranded and copper wires with a cross-sectional area of not less than 2.5 square millimeters. After grounding, the resistance between the fuselage and the main grounding point should be less than 4 ohms.

(4) Connect to the power supply

Input voltage 380V, frequency 50HZ power supply.

(5) Connect to the air source

Install the air source on the joint of the air source treatment triplet on the side of the fuselage, and adjust the air pressure to 0.5-0.8MPa after checking that there is no air leakage.

(6) Check the oil circuit

Open the back cover of the machine body, and the liquid level of the oil tank should be kept above the middle line of the oil mark to prevent the oil pump from being emptied. When refueling, use a 120-mesh filter to filter out the impurities in the new oil.

- Faults and troubleshooting methods

(1) If the triplet pressure does not rise, check the pressure regulating valve spring, and replace it in time if it breaks.

(2) When the lubricator does not drip oil during the working process, check whether the inlet flow rate is reduced and whether the oil pinhole is blocked by dust.

(3) Refer to the electrical schematic diagram and electrical wiring diagram analysis for electrical system failures.

(4)Troubleshooting of hydraulic and pneumatic system failures, consult the schematic diagram of the pneumatic hydraulic system for analysis.