Aluminum window especially the thermal break window is more and more popular in today’s world. People love it because of its excellent thermal insulation properties. Besides of the good design and high-quality materials(aluminum profile, glass, strips, sealant, etc), what else make the thermal break window function so well? The answer is the way to make the windows.

To make aluminum windows, we must need aluminum window machinery including aluminum profile cutting saw, crimping tool, aluminum punching machine, aluminum bending machine, end milling machine an so on. For all the machines above, the aluminum profile cutting saw is the most important one. Usually, the window jamb and sash profiles are jointed at 45degree angle. And the mullion profiles are connected to the jamb at 90 degree. So, cutting 45 degree and 90 degree angle is the basic function required for the cutting saw. The double head miter saw is made for this purpose.

JMD is the leading manufacturer of aluminum window machinery in China. We have 2 models of double miter saw optional:

- LJJ2AS-500X4200, CNC controlled. The right machine head can move automatically to reach the cutting length. Cutting length can be preset through the touch screen. It’s easy to operate, especially when you have multiple cutting lengths.

2. LJJ2AX-500X4200, Non-CNC. The right machine head should be manually moved to reach the cutting length. The real cutting length will be displayed by a digital screen. Compared the the CNC saw, it is more simple and stable. More importantly, its price is not high.

Which saw will you choose? Feel free to contact us if you’re interested.

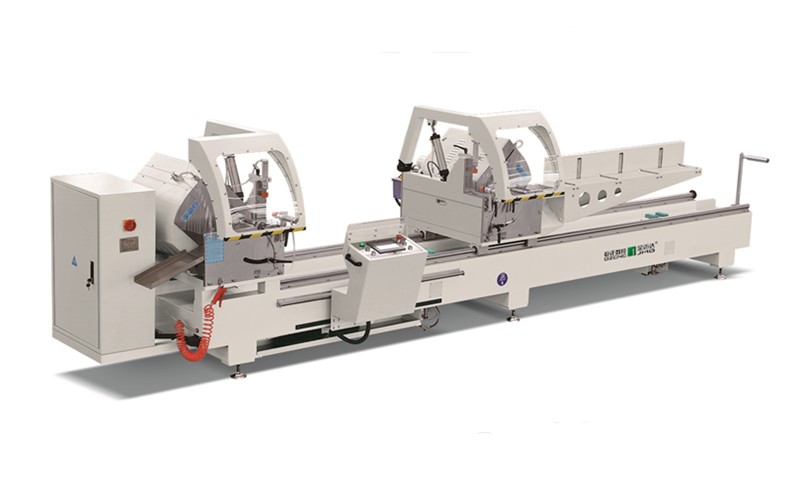

]]>Double Miter Saw is a profile cutting tool used in the production of doors and windows.

The left saw head is a fixed saw head, and the right saw head is a movable saw head, which can be moved left and right on the circular guideway. Each saw head is composed of swing angle mechanism, feed system, worktable, workpiece clamping system, saw blade, saw cover, etc.

The swing angle mechanism is driven by the cylinder and positioned by the limit block.

The feed system is driven by a cylinder and fed in a straight line.

The saw blade is driven by the spindle motor, and the feed system is the core component of the saw head, which should be maintained and maintained in use.

The worktable is used for profile support, positioning and installation of clamping mechanism, saw cover protection and chip collection function.

- Schneider CNC system & automatic profile supporting system

- Driven by rack, the right machine head horizontally moves with precise repeat orientation,The repetitive positioning accuracy can reach 0.02mm.

- Available to input a series of data (cutting length & quantity) to realize the continuous cutting

- Saw blade:Diamond ZhiGuang; Cable & electric wires: YiChu; Pneumatic components: AirTAC

- Saw blade feeding driven by hydraulic damping cylinder through HIWIN linear guide rail pair

Aluminium Double Head Mitre Saw Cutting Machine

CNC Double-head Miter Cutting Saw for Aluminum Curtain Wall (Arbitrary angle)

Saw blade speed: 2800r/min; Sawing length: 360~5000mm

Digital Display Double-head Miter Precsion Cutting Saw for Aluminum and PVC Profile

Cutting angle: 90°, 45°; Cutting length: 270~4200mm

CNC Double-head Miter Precision Cutting Saw for Aluminum and PVC Profile

Cutting angles: 90°,45°; Cutting length: 320~4200mm

]]>