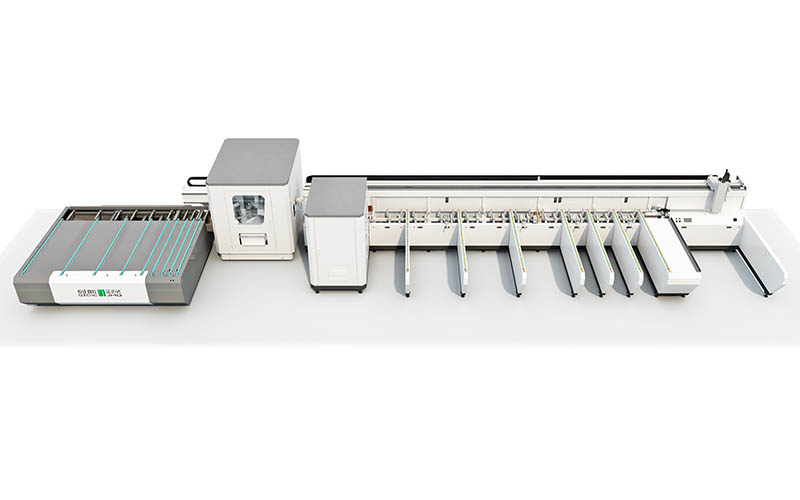

Thermal break aluminum window Jamb have mainly three processes: 45 °cutting,milling holes(glue injection hole, pin hole, mullion connection hole, water drainage, mounting hole ), corner crimping

JMD recommend two type of machines for 45 ° cutting function& milling holes function

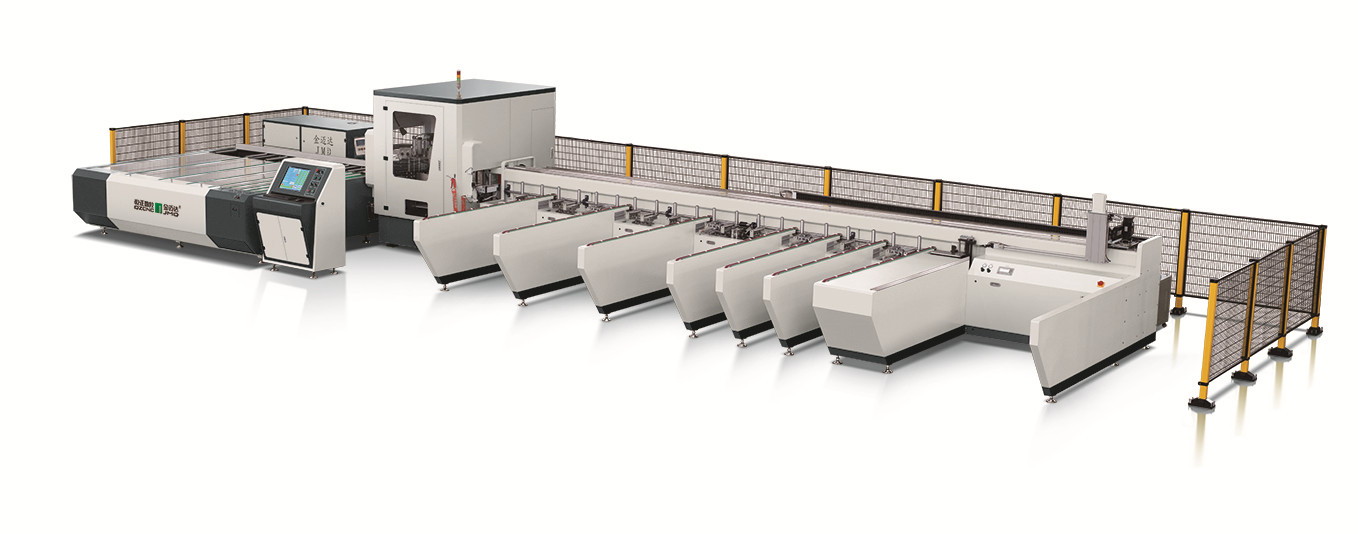

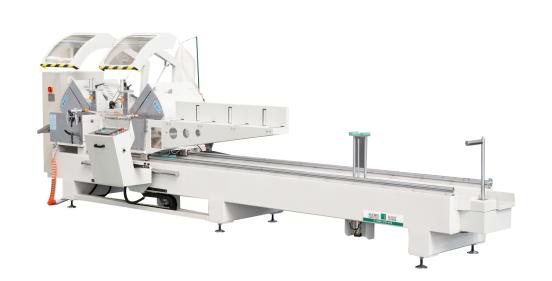

No.1 Frame production line (LJCKB-6500)with production capacity 800m2 /day

No.2 CNC Machining Center(LJZX4-6500) with production capacity 200m2 /day

JMD recommend Heavy duty Corner Crimping Machine(LJZJZ-150) for corner crimping function

]]>

Aluminum windows are more and more popular in today’s world. If I want to start the business of it, what should I do?

First, we need to confirm what kind of windows to make, sliding windows, casement windows or swing windows? Then to find the aluminum profile supplier.

Second, find the right window machines which suitable for the profiles. As there’s no universal machines can make all kinds of windows, we have to make sure the machines are available for the profiles, that’s why we need to confirm the profile supplier first. If we want to make thermal break casement windows, basically, we’ll need double miter saw, corner crimping machine, end milling machine, copy router/CNC milling machine, punching machine and corner connector saw, etc.

Before buy the machines, we’d better send some aluminum samples to the machine suppliers to confirm they machines can process the profiles. Don’t forget to order enough wearing parts for the machines such as saw blades, milling cutter and crimping knives, etc. As the window machines need to work with compressed air and electricity, you also need to buy an air compressor, air tank, air hose and cables, etc.

Besides of the big window machines, we also need to buy some small tools such as meter stick, protractor, vernier caliper, gradienter, pencil, electric drills and chop saw, etc.

Then, we need to find supplier of glasses, sealants, hardware and rubber strips, etc.

To make aluminum windows is not a easy job, you also need some other tools or materials,but if you get all the items mentioned above, you can start the job. Good luck!

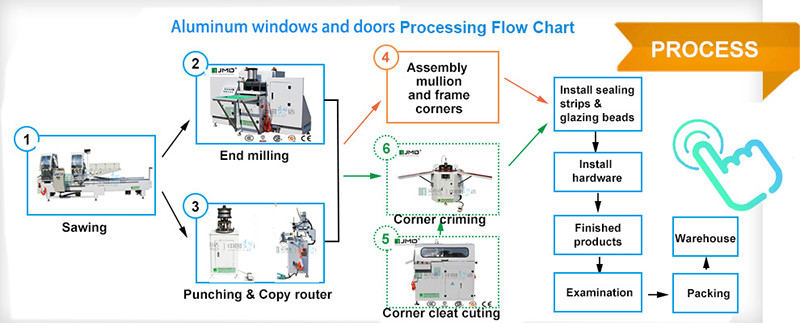

]]>In the door & window machine industry for 23 years,it is found that the customers you encounter usually have a habit:

Likes to negotiate prices with high-end devices,talking about quality with low-end devices.

Customers will say: The CNC double-head cutting saw from another brand in China is exactly the same as yours, why is yours so expensive? please see below,can this be the same?

As the saying goes,”dilettante watch the scene of bustle, experts see road”. For example,for a aluminium CNC double head cutting saw,What you see is a similar look and cutting method. Do you really know the internal structure of the device?

First of all, the body is the basis and premise to achieve machining stability What kind of aluminum is used for the body?

Are body bevels handled and cleaned up to standard before welding?

Are preheating temperatures and inter layer temperatures properly controlled?

Does the soaking and drying of the body after welding meet the requirements?

Secondly, the choice of parts and operating system is the soul of cutting Precision. JMD aluminum profile cutting operating system, servo motor and all electrical parts are using Famous brand from domestic and overseas Effectively ensure the coordinated operation of all electrical components Thus greatly improve the cutting precision, surface flatness and cutting efficiency.

Lastly, the company’s after-sales service system. After-sales service is not the same as only dealing with unexpected problems of equipment. JMD after-sales service system is including plant layout, doors and Windows production process diagram, training engineering and technical personnel, software technology training as well as equipment installation and commissioning, on-site production guidance, until the production of qualified products and other whole process services.

So when you actually have the patience to compare two devices that you think are “identical” ,do you still ask the same question you wanted to ask?

Business is about honesty. Please believe that quality and price is always proportional to the truth!

Different machine is used in the production of doors and windows, so higher requirements are also placed on the operators of window machinery. During the use of some window machine, hidden faults often occur, resulting in interruption of production activities, which requires Regular maintenance and repair of machinery and machine can play a preventive role and ensure efficient production efficiency. If the mechanical machine is not maintained and maintained for a long time, it will cause the wear and tear of the parts. Once the failure occurs in the production, the losses will be more serious.

Let’s talk about the maintenance of door and window machine below.

Lubrication of bed guides and working guides: use 40# mechanical oil or 46# anti-wear hydraulic oil in summer; use 30# mechanical oil or 32# anti-wear hydraulic oil in winter.

Adjustment of the air source processor (oil-water separator, pressure reducing valve, lubricator): the oil-water separator is a differential pressure drainage type, and the compressed air should be closed after the machine is shut down to discharge the accumulated water; the pressure gauge is adjusted to 0.5~0.8 MPa; the lubricator ensures a certain oil level (mechanical oil 20#), and the oil volume is adjusted to about three drops per minute.

The machine should be kept clean, and the aluminum scraps should be cleaned in time after each shift; the dust on the guide rail and the surface of the machine tool should be wiped off, and the exposed surface of the guide rail should be smeared with grease to prevent rust.

Clean the aluminum chips and dirt inside the machine head once a month (the cover needs to be removed). In particular, the work-in linear guides should be wiped clean, and lubricated and moved back and forth several times to observe whether there is a stuck phenomenon, and if there are any problems, they should be solved in time.

When the machine is used for the first time and after being placed for a long time, it should be carefully checked before running.

For the cooling and lubrication of the milling cutter, we first recommend using kerosene; secondly, special cutting fluid for aluminum profiles without water can be used.

We strongly advise against the use of emulsified oils and water-based cutting fluids.

Common faults and solutions

After the first use or after the device is reconnected to the power supply, if the operating device does not work, first check whether the power supply has electricity; then check whether the phase sequence protection relay indicator light in the device distribution box is lit. If not, please exchange any two-phase live wire of the power cord.

The pressure reducing valve cannot reach the working pressure: first check the output pressure of the air compressor. If the output pressure of the compressor reaches, then check whether the pressure regulating valve spring is broken or whether the pipeline is leaking. If there is any problem, repair or replace it in time.

If the lubricator does not drip oil during operation, check the oil quantity of the oil cup, or check whether the oil needle hole of the lubricator is blocked, and repair or replace it if there is any problem.

Electrical or pneumatic system failure: refer to the electrical schematic diagram and the gas circuit schematic diagram, and professionals can take professional methods to analyze, find and eliminate, or directly contact the machine manufacturer.

Edited by JMD

The demand for thermal break aluminum doors and windows in the market is increasing year by year, and the scope of application is gradually expanding. As we all know, we are accustomed to opening windows every day, and the utilization rate of windows is very high. Well, in the face of such a high utilization rate of door and window equipment, and there is no real operation before buying the equipment, so here are some details of the installation and debugging of door and window equipment.

First, in terms of electricity. Voltage 380V is the normal voltage of general door and window machinery, and the frequency is 50Hz. Therefore, the connection between the live wire and the neutral wire needs to be paid attention to. The live wire and the neutral wire must be connected well, otherwise it may cause an accident. Generally speaking, most door and window equipment manufacturers distinguish by color, the live line is black or blue, and the zero line is red. If the live wires are reversed, just change the two wires.

Second, in terms of gas supply. Since the pressing material of the door and window equipment must ensure sufficient air supply, it can be used better. Under normal circumstances, the air supply and air pressure of door and window equipment are required by fixed parameters. The air supply flow must reach 0.3 and the air pressure must reach 8 pressures. In the case of multiple door and window equipment, it is necessary to prepare more gas storage tanks, which depends on the actual situation. If the air pressure is not reached, the accuracy of the door and window processing equipment will have some influence, and the corresponding processing effect will also deviate from expectations.

Third, the equipment. There are many types of thermal break aluminum doors and windows, and each type of equipment has multiple models, or multiple equipment parts are different, and so on. Therefore, in the installation and debugging of door and window equipment, it is necessary to coordinate the work of each area and grasp each world, so that there will be no problems in debugging.

As a manufacturer of aluminium door and window machine, I don’t know how much you know about the daily maintenance of aluminum doors and windows machines. Now let’s talk about this issue for everyone.

1. Check mechanical parts and fasteners to prevent loosening. Every conveying part must be regularly lubricated, and the movable head rail must be regularly lubricated every week. The oil cup keeps a certain amount of oil, the circulating water of the water tank is replaced every day, the water tank is cleaned regularly every week, the nozzle is frequently checked, and the plug is found and cleaned in time. The working surface and jaws of the board fitter, the upper and lower pressing pliers should be kept clean and oil-free, and scrubbed every shift.

2. When not in use, the machine tool is cleaned up, and then the rust prevention of the circular guide rail and other moving parts is completed. The electrical control box is kept clean, cleaned frequently, and dried with an air gun. Regularly overhaul the on-site power supply system of the equipment, and check the phase and neutral relationship of the power supply system. Check the high-pressure hose regularly. Long-term use of high-pressure hoses will cause aging and damage everywhere, and the pressure resistance of the hose will decrease. The air source processor needs to be cleaned regularly, and the pressure gauge needs to be properly adjusted. The storage environment of the machine should be kept dry and free of moisture and corrosive gases to avoid damage to the machine.

3. Frequently check whether the shower equipment needs to be added with coolant, check the mechanical screws and fasteners to prevent loosening and affect the use, especially the travel switches behind the two heads. The machine should be kept clean. After each shift, clean up the chips in time, wipe the dust on the surface of the guide rail and the machine, add lubricating oil to the exposed surface of the disc guide rail and apply uniform paint. For equipment that will not be used for a long time, corresponding cleaning and maintenance work should be done, and the protective cover can be properly covered.

Regular maintenance of aluminum alloy processing equipment can not only reduce hidden dangers, but also extend the service life of the equipment and improve the working efficiency of the equipment. In fact, it is of great significance.

]]>The corner crimping machine is a special equipment for the production of high-grade broken bridge aluminum doors and windows, which is suitable for 90 degree angle connection of corner structure aluminum doors and windows. According to the different angles that can be assembled, it is divided into single-head corner crimping machine, double-head corner crimping machine, and four-head corner crimping machine.

Principle and structure:

- Main components

The corner crimping machine is composed of main parts such as body, worktable, positioning cylinder, riveting device, corner crimping cylinder, corner crimping slide, electric control panel, foot switch and so on. The pneumatic system consists of solenoid valves, pressure gauges, mist, water separators, etc. The hydraulic system is composed of hydraulic pump, solenoid valve, high pressure hose, hydraulic relay, etc. - Working principle

The corner crimping cylinder pushes the corner crimping slide, which moves forward, and simultaneously pushes the left and right riveting shafts. The corner crimping knives on the riveting shaft realize the 90-degree connection of aluminum doors and windows

- Structural features

This machine is a new model developed on the basis of absorbing the advantages of similar foreign products. This machine adopts pneumatic, electric, hydraulic and operation control. Due to the new mechanical linkage structure, the influence of oil pressure fluctuations on the quality of the group angle is eliminated, the group angle is completely synchronized, the group angle depth is more consistent, and the group angle is 90 degrees The angle is more accurate. In addition, the front and rear positioning adopts the up and down adjustable positioning device, and the front and rear distance adjustable positioning device is suitable for processing profiles with different cross-sectional shapes and sizes. - Installation

(1) Environment and requirements

The corner crimping machine should be installed on a dry, dust-free, and non-corrosive indoor hard cement floor.

(2) Out of the box in place

After unpacking, move the corner crimping machine together with the packaging base to the installation position, remove the fastening screws of the corner assembly base, and use the moving tool to move the corner crimping machine to the installation position.

(3) Ground

The frame of the corner crimping machine should be grounded. When grounding, use yellow and green double-color stranded and copper wires with a cross-sectional area of not less than 2.5 square millimeters. After grounding, the resistance between the fuselage and the main grounding point should be less than 4 ohms.

(4) Connect to the power supply

Input voltage 380V, frequency 50HZ power supply.

(5) Connect to the air source

Install the air source on the joint of the air source treatment triplet on the side of the fuselage, and adjust the air pressure to 0.5-0.8MPa after checking that there is no air leakage.

(6) Check the oil circuit

Open the back cover of the machine body, and the liquid level of the oil tank should be kept above the middle line of the oil mark to prevent the oil pump from being emptied. When refueling, use a 120-mesh filter to filter out the impurities in the new oil.

- Faults and troubleshooting methods

(1) If the triplet pressure does not rise, check the pressure regulating valve spring, and replace it in time if it breaks.

(2) When the lubricator does not drip oil during the working process, check whether the inlet flow rate is reduced and whether the oil pinhole is blocked by dust.

(3) Refer to the electrical schematic diagram and electrical wiring diagram analysis for electrical system failures.

(4)Troubleshooting of hydraulic and pneumatic system failures, consult the schematic diagram of the pneumatic hydraulic system for analysis.

With the vigorous development of the door and window industry, many bosses who are optimistic about the prospects of the door and window industry are planning to develop in the processing of doors and windows. As door and window products gradually move toward high-end, the past era of processing doors and windows with a small cutting machine and a few small electric drills has gradually gone.

To produce high-performance doors and windows, high-performance door and window equipment is essential. Which machine consists of a complete door and window production line, we must understand:

- Double head cutting saw

The double-head cutting saw is used to cut aluminum alloy profiles. The accuracy of sawing directly affects the quality of doors and windows, so double-head saws are essential equipment for the production of doors and windows. There are many varieties of double-head cutting saws on the equipment market. For example: Manual, digital display, CNC. Specially cut 45 degrees, there are also 45 degrees and 90 degrees. The price ranges from tens of thousands to hundreds of thousands. This depends on the product positioning and investment budget to decide which level to buy.

- Copy Router

Through the design of the profiling plate and profiling processing, the processing of a variety of regular and special-shaped holes and grooves can be realized, and at the same time, the processing of the keyhole can be completed in one clamping.

- Punching Machine

Mainly used for punching of various profiles of doors and windows

- Corner Connector Cutting Machine

The aluminum door and window corner connector cutting saw is a special equipment for cutting the corner cconnector. It has high strength, stable performance, high processing precision and simple operation.

- Crimping Machine

The corner crimping machine is a special equipment for the production of high-grade broken bridge aluminum alloy doors and windows, which is suitable for 90-degree angle connection of corner structure aluminum doors and windows. In some areas, it is also called corner squeezing machine, corner collision machine, and corner corner machine. According to the different angles that can be assembled, it is divided into single-head angle forming machine, double-head angle forming machine, and four-head angle forming machine.

- End milling machine

Used for forming the end face, step face and end groove of the mullion.

In summary, the six types of equipment are necessary equipment for the production of doors and windows.

]]>

Aluminum profile multi-head drilling machine is mainly used for drilling profiles of aluminum alloy doors, windows and curtain walls, especially for long materials and mass production.

It is suitable for profiles whose cross section does not exceed 250*250mm, and the maximum machining length is 5000mm~6000mm.

Multi-head drilling machine can be installed to meet the simultaneous machining of multiple groups of holes.

The gas-liquid damping cylinder is used in the feed system, and the feed is stable.

First of all, we need to select the appropriate bit and bit according to the material and drilling depth of the processed object, and the common bits on the market are also matched with a variety of hardness according to different materials.

Secondly, it needs to be adjusted to the speed of the motor suitable for processing materials, too high speed is easy to soften low melting point metal, too slow soft materials will have adhesion.

Of course, we need to do a good job of cooling and lubrication.

JMD Multi Head Drilling Machine Products

Chassis brand: JMD

Max Dia. Drilling hole

Max distance of two drilling hole

Benefits & Features

1. This machine is mainly composed of six sets of drilling head,bed

electrical control system and pneumatic system;

2. Each drilling head is composed of motor, three-axis drill pack, sprayer,

pneumatic feeding, workbench, profile clamping cylinder, profile support

structure, head locking structure and electrical operating panel.

3. PLC control, all the heads working can be single action and linkage,it

depends.

4. Each operating button refer to “operating panel photo”.

The price of wooden window ranges from tens of thousands to more than one hundred thousand, which should be decided according to the positioning of their own products and the investment budget. The editor suggests that when the capital budget is sufficient, try to choose the one with high accuracy.

Wood window machine (Wood window making machinery) including Double-head cutting saw, Copying milling, End milling machine.

- Double-head cutting saw.

Double-head cutting saw is cutting materials for aluminum alloy profiles, and the accuracy of the saw directly affects the quality of windows and doors produced. Now there are many kinds of double-head cutting saws in the equipment market, including manual, digital display, numerical control, and special 45-degree angles. there are also those that can cut 45 degrees and 90 degrees. - Copying milling.

Used for milling lock hole, drain hole, handle hole, hardware hole, this is necessary. - End milling machine.

The end milling machine is mainly for milling the end face of the atrium of doors and windows, and different equipment types are selected according to the type of doors and windows to be produced, which are used in the production of building doors and windows, broken bridge doors and windows, broken bridge window screen integrated windows and aluminum doors and windows.

Depending on the type of equipment, some can only mill one material at a time, while others can mill multiple materials at the same time.

What are the benefits of wooden windows?

- Durable and undeformed Yuanwang wood window uses Korean pine lumber imported from Europe with advanced technology as raw material.

Integrated wood is a kind of material in which the short wood is re-lengthened by advanced finger joining technology after removing defects such as grease, decaying parts, cracks and wormholes, and then laminated.

By reassembling the wood, the integrated wood avoids the disadvantage that the naturally grown wood is easy to deform because of its own internal stress, and solves the deformation problem caused by the climate change in the use of wood. - Good sealing effect, high energy saving and manic reduction compared with traditional wooden doors and windows, Yuanwang wooden windows are closely jointed after precision machining with advanced equipment and cutting tools, and sealing strips are used in the joint of window frames and sash. It can prevent the internal and external air from circulating each other through the gap between the window frame and the window sash, as well as the invasion of external wind and sand and Rain Water.

At the same time, the glass used is a double-layer hollow glass filled with inert gas inside, which can effectively prevent the indoor heat from dissipating. - Wood is easier to heat transfer and dissipate heat, and the window has a double-layer hollow glass structure, which makes it have good anti-irritability performance and can reduce noise 35dB.