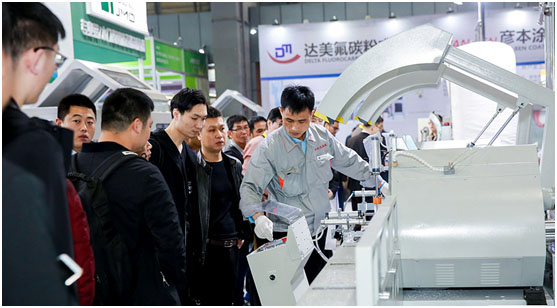

CNC Corner Connector Cutting Saw (Angle code saw is a professional door and window cutting equipment used by door and window processing enterprises to cut aluminum angle code when producing broken bridge aluminum doors and windows. at present, it is mainly divided into heavy automatic angle code cutting saw, semi-automatic angle code cutting saw and numerical control angle code cutting saw.

- Schneider CNC system; Cable & electric wires: YiChu; Pneumatic components: AirTAC; Saw blade: Janpan DaHe

- Profile feeding driven by ball screw rod. Saw blade feeding driven by air-liquid damping cylinder

- Cutting width & quantity preset by touch screen

- Machine body is overall structure with good rigidity

LJJM-450(500)*100

Auto Corner Connector Cutting Saw for Aluminum Doors and Windows

Cutting length:3-100mm; Cutting width*height:100x120mm

Benefits & Features

1.Cable & electric wires: ShangHai YiChu; Pneumatic components: AirTAC; Saw blade: Janpan DaHe

2.Profile feeding & saw blade feeding both driven by air-liquid damping cylinder

3.Cutting quantity digital displayed

4.Machine spindle made by professional manufacturer

5.Machine body is overall structure with good rigidity

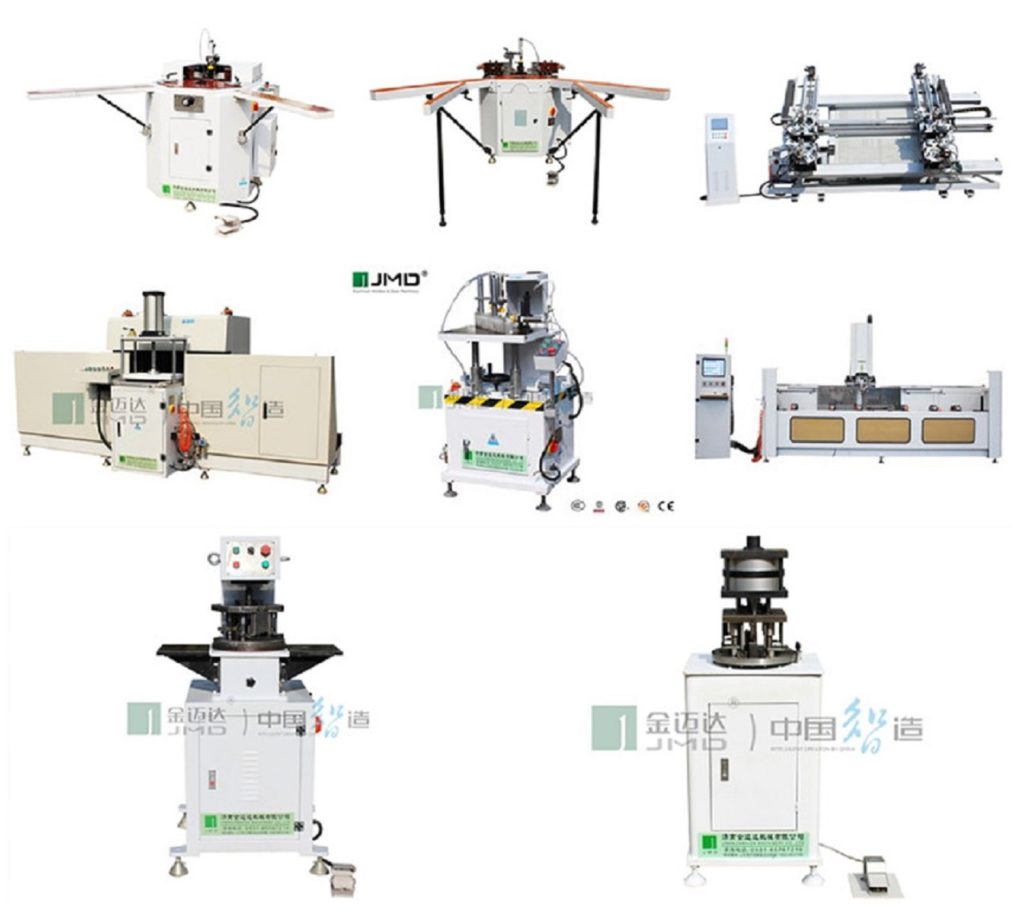

Aluminum window and door equipment includes many, cutting saws, angle machines, milling machines and so on.

The double-end cutting saw of heat-insulated aluminum window and door mainly includes numerical control precision cutting saw, digital display precision cutting sawing machine, precision cutting sawing machine and ordinary double-end cutting sawing machine.

Among them, CNC precision cutting sawing machine has the advantages of high processing speed, high efficiency and high precision.

The processing effect of digital display precision cutting sawing machine is the same as that of precision cutting sawing machine, except that the former has digital display function, so people can use digital display meter to determine the length more conveniently, quickly and accurately, and improve the efficiency of door and window processing.

Both of them are very suitable for medium-scale projects of thermal insulation broken bridge aluminum window and door equipment.

As for the ordinary double-head cutting sawing machine, that is, what we usually call “saw king” or “06 saw”, it is the earliest research and development and use, and it is also a relatively simple window and door equipment.

For customers with an annual output of less than 10,000 square meters, this double-ended saw is the best choice for you to buy broken bridge aluminum window and door equipment.

Compared with the previous 06 saw, the current saw machine adds a special solenoid valve for spray, which enhances the lubrication function of the equipment and prolongs the service life of the saw blade.

Aluminum window and door equipment is an important machine for processing and producing window and doors, which will be more widely used in many fields.

There are many types of equipment involved, including cutting, angular assembly, welding, etc., different equipment involves different types of processing, so what are the components of aluminum window and door equipment?

Components of aluminum window and door machine-cutting machine.

In the use of equipment can not be separated from the use of cutting equipment, there is no doubt that cutting equipment plays a very important role in the process of processing.

When using the equipment, you can well complete the material cutting of the equipment and the change of the angle length, and at the same time, there is a certain distinction when using the machine, including the degree of automation and operational performance and so on. these factors are not only the key factors that affect the later use, but also the factors to be considered according to their own reality when choosing cutting equipment.

Components of aluminum window and door machine-welding part.

When using the equipment, we also need to consider the welding, the welding of the equipment plays a very important role and performance, the welding of the equipment can better help the corresponding parts to connect.

There are many welding methods of machine, including the use of rare gas for welding and so on. Rare gas protection is needed when using the machine, which needs to be classified according to the way of welding, which is also a key factor in the use of equipment.

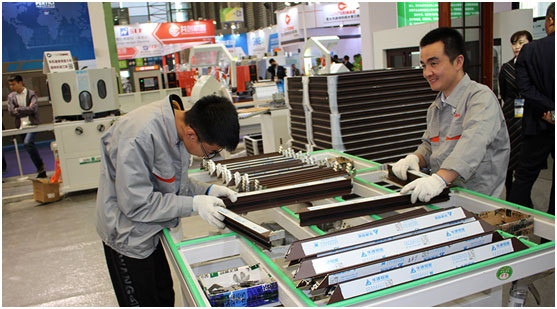

Components of aluminum window and door machine-angle machine.

Correspondingly, when using the machine, it is necessary to use the angle equipment.

What is the angle equipment?

To put it simply, this kind of machine is an important decoration equipment when processing windows and doors, the angle of the equipment needs to be controlled is the size and angle, part of the equipment in the use of the process of adding a special PLC control technology, the necessary PLC control technology is a reasonable collocation of equipment programming, the use of computer programs to link up, so as to better meet the processing needs.

In a word, the components of aluminum window and door equipment are carried out according to the equipment processing steps, and it is very important for users to choose the right aluminum window and door equipment merchants. Shandong JMD is a professional equipment provider with a good choice and performance. interested customers are welcome to choose us. I believe our service will not let you down.

]]>Aluminium windows and door processing machine is the machinery needed for processing and making aluminium doors and windows.

Aluminium door and window machines are divided into four categories: cutting machines, crimping machines, milling machines and punching machines.

Regarding cutting machinery, our company has CNC cutting centers, CNC double-head saws, digital display double-head saws, Corner connector cutting saws, etc.

Regarding the corner crimping machine, our company has three types of it, CNC four-head corner crimping machine, heavy duty crimping machine and light duty crimping machine.

Our company also has end milling machine, drilling and milling machine.

And the punching machine.

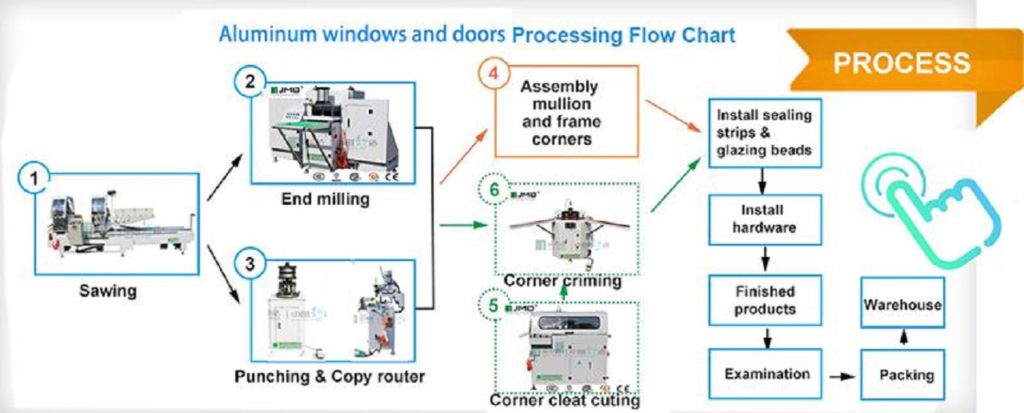

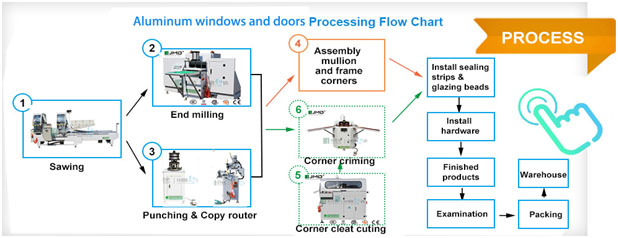

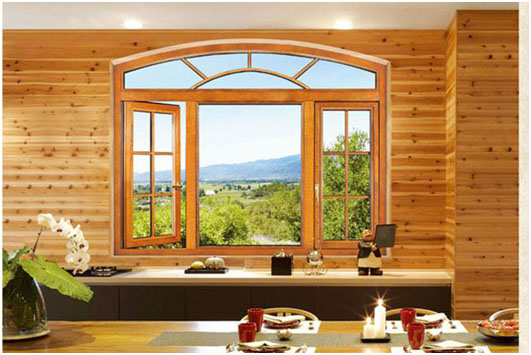

There are many kinds of doors and windows. According to the materials, we can divide them into aluminum windows, UPVC windows, and wooden windows. According to the opening mode of windows, they can be divided into open windows, sliding windows, downward rotating windows and so on. We will explain how to make aluminum open windows and the making process.

Let’s take a look at the aluminium windows production flow chart

(1) Prepare materials.

To know the specifications windows, and then prepare the corresponding models of aluminum profile, glass, glass sealant, door and window accessories. Next is the necessary things: aluminum double head cutting machine, corner cutting machine, punching, profiling end milling machine, window milling drilling machine and so on.

(2) Frame, casement, mullion, glazing bead profile, cutting.

Cutting material is the first and key process of aluminum windows. The cutting material is mainly cut by double head saw, and the material length shall be determined according to the design requirements and referring to the detailed drawing of door and window construction. General cutting is divided into 90 cutting, 45 degree cutting. Cutting equipment model can refer to: ljj2as-500 * 4200

(3) Mullion processing

Mullion processing: the middle stile is generally 90 degree splicing, After cutting, end milling is required ,and the end milling machine model ljx4-250 or ljxb-200 is generally used

(4) Aluminum window assemble.

(4) For drilling or punching, the aluminum frame and casemetn is generally connected with screws, so whether it is the assembly of horizontal and vertical members or the fixation of accessories, it is necessary to drill holes at corresponding positions. For profile drilling, small bench drill or pistol electric drill can be used. The former can effectively ensure the accuracy of drilling position due to its worktable, while the latter is due to convenient operation.

Aluminum window assemble. According to the requirements of construction detail drawing, the profiles are connected and assembled by connecting pieces with screws. There are three assembly methods of aluminum doors and windows: 45 ° angle butt joint, right angle butt joint and vertical butt joint. The connection of horizontal and vertical bars generally adopts special connector or aluminum corner, and is fixed with screws, bolts or aluminum corner.

(5) Installing glass

The glass should be uniform and symmetrical in the installation groove, and meet the requirements of glass embedding size in the specification. When installing glass with adhesive tape, the outer rubber strip can be installed first, and then the inner adhesive strip can be installed after adjusting the position of glass with enough rubber pad on the inside. After installation, the adhesive strip should be straight, without wrinkle and bulge, and the joint should be well bonded.

5.1When installing glass with sealant, the position of glass can be adjusted with enough rubber pad in the aluminum frame, and then sealant shall be applied. The sealant shall be neat, smooth and smooth without gaps, fractures and cavities. The width of glue injection shall not be less than 5mm and the minimum thickness shall not be less than 3mm.

5.2 The 45 ° or 90 ° joint can be used for the glazing bead. The glass should be removed carefully before installation. The joint position should not be scratched during the installation. The joint is tight and flat without cocking after installation.

6: Packaging.

After the semi-finished products are assembled and inspected, they can be cleaned and sealed with the certificate of conformity. In the production process, the technical personnel should achieve each process standard, and the glass inside and outside must be sealed with glass glue. In the production process, the most important thing is to pay attention to the size of the problem, if the size is wrong, that is the most troublesome.

Summary, there are many door and window styles, production methods have a variety , welcome your comments and ideas.