Overview of window and door machine maintenance

25 May, 2022

Lubrication of bed guides and working guides: use 40# mechanical oil or 46# anti-wear hydraulic oil in summer; use 30# mechanical oil or 32# anti-wear hydraulic oil in winter.

Adjustment of the air source processor (oil-water separator, pressure reducing valve, lubricator): the oil-water separator is a differential pressure drainage type, and the compressed air should be closed after the machine is shut down to discharge the accumulated water; the pressure gauge is adjusted to 0.5~0.8 MPa; the lubricator ensures a certain oil level (mechanical oil 20#), and the oil volume is adjusted to about three drops per minute.

The machine should be kept clean, and the aluminum scraps should be cleaned in time after each shift; the dust on the guide rail and the surface of the machine tool should be wiped off, and the exposed surface of the guide rail should be smeared with grease to prevent rust.

Clean the aluminum chips and dirt inside the machine head once a month (the cover needs to be removed). In particular, the work-in linear guides should be wiped clean, and lubricated and moved back and forth several times to observe whether there is a stuck phenomenon, and if there are any problems, they should be solved in time.

When the machine is used for the first time and after being placed for a long time, it should be carefully checked before running.

For the cooling and lubrication of the milling cutter, we first recommend using kerosene; secondly, special cutting fluid for aluminum profiles without water can be used.

We strongly advise against the use of emulsified oils and water-based cutting fluids.

Common faults and solutions

After the first use or after the device is reconnected to the power supply, if the operating device does not work, first check whether the power supply has electricity; then check whether the phase sequence protection relay indicator light in the device distribution box is lit. If not, please exchange any two-phase live wire of the power cord.

The pressure reducing valve cannot reach the working pressure: first check the output pressure of the air compressor. If the output pressure of the compressor reaches, then check whether the pressure regulating valve spring is broken or whether the pipeline is leaking. If there is any problem, repair or replace it in time.

If the lubricator does not drip oil during operation, check the oil quantity of the oil cup, or check whether the oil needle hole of the lubricator is blocked, and repair or replace it if there is any problem.

Electrical or pneumatic system failure: refer to the electrical schematic diagram and the gas circuit schematic diagram, and professionals can take professional methods to analyze, find and eliminate, or directly contact the machine manufacturer.

Edited by JMD

Related Product: Window machine

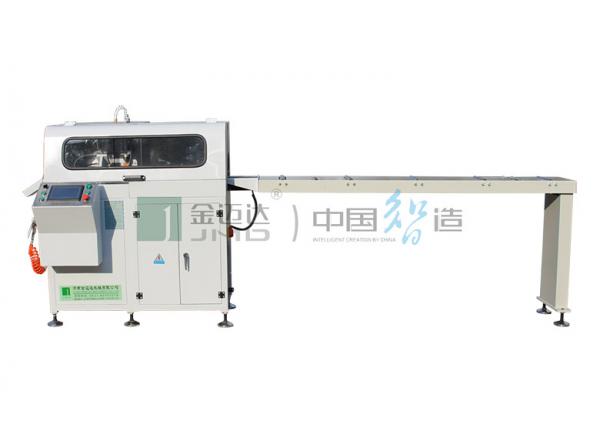

CNC Corner Key Cutting Saw, Aluminum CNC Machine

CNC Corner Connector Cutting Saw for Aluminum Doors and Windows

CNC Corner Connector Cutting Saw, Aluminum CNC Machine

CNC Corner Connector Cutting Saw for Aluminum Doors and Windows

Aluminium Window Corner Connector Cutting Saw

Auto Corner Connector Cutting Saw for Aluminum Doors and Windows

Window machine, Window machine Window machine maintenance Aluminum machine,