What is the difference between CNC saws for window and doors equipment and ordinary double-headed sa

17 May, 2022The so-called CNC saw is CNC fixed-length, that is, when the movable head moves, it is numerically controlled. This is the main difference. When the ordinary double-head saw is fixed to length, it is manually operated, and the movable head is pushed to the required size position, and then After fine-tuning to the required size, lock the movable machine head. As for the length cutting accuracy, the CNC error is within 0.2 mm, and the length cutting error of the ordinary double-headed saw is withi......

Matters needing attention when working with double-head cutting saw for aluminum alloy windows and d

22 Apr, 2022When the double-head cutting machine for aluminum alloy profiles cuts industrial aluminum profiles or aluminum alloy profiles with thermal insulation and broken bridges, JMD?Machine reminds customers to pay attention to the following points:Application range of aluminum alloy profile double-head cutting saw: aluminum profile CNC cutting saw adopts soft transmission technology, magnetic ruler positioning, Chinese touch screen display1. Pay attention to the spray device. When cutting thick alumin......

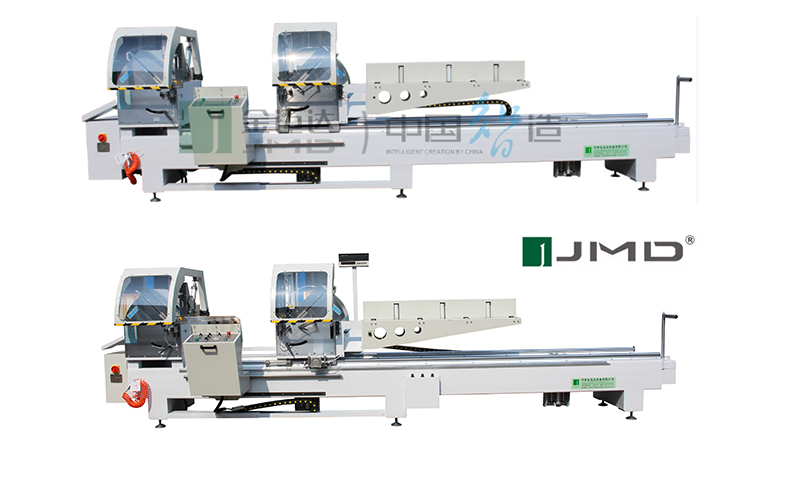

Advantages of aluminium double head cutting saw

23 Jul, 20211.?The double-head cutting saw is a profile cutting tool used in the production of doors and windows. It is suitable for cutting aluminum and plastic profiles. The transmission and feed of the sawing machine are controlled by a numerical control system. The cutting size has high precision, simple operation, reliable performance, and advanced technology. The cutter adopts cemented carbide circular saw, which has fast cutting speed and high production efficiency. It is an ideal equipment for the ......

How to choose an aluminum cutting saw?

03 Jun, 20211. Look at the appearance, see whether the frame is solid and whether the appearance details of the aluminum profile cutting saw are handled properly.?2. look at the inside, have a deep understanding of its internal performance, functional characteristics, and make choices based on your own needs.3. Looking at processing, good equipment depends on assembly. Companies with a long time to build factories often have a group of experienced and skilled assembly technicians. With years of accumulatio......

What is the best saw blade to cut aluminum?

17 May, 2021Under normal circumstances, aluminum alloy cutting saw blades are used inlaid alloy saw blades, and the saw blades are inlaid with cemented carbide. For the tooth profile, the saw blades for cutting aluminum alloy are all ladder flat teeth.For different aluminum alloy materials, the number of teeth used by aluminum alloy cutting saw blades is very different. Of course, generally speaking, the thicker the material wall to be sawed, the fewer the number of teeth of the aluminum alloy saw blade use......

What is CNC Corner Connector Cutting Saw?

04 Mar, 2021Angle code saw is a professional door and window cutting equipment used by door and window processing enterprises to cut aluminum angle code when producing broken bridge aluminum doors and windows. at present, it is mainly divided into heavy automatic angle code cutting saw, semi-automatic angle code cutting saw and numerical control angle code cutting saw.1.?Schneider?CNC?system; Cable & electric wires: YiChu; Pneumatic components: AirTAC; Saw blade: Janpan DaHe2.?Profile feeding driven by ......

What is aluminium cutting machine?

28 Jan, 2021Aluminum window and door?equipment includes many, cutting saws, angle machines, milling machines and so on. The double-end cutting saw of heat-insulated aluminum window and door mainly includes numerical control precision cutting saw, digital display precision cutting sawing machine, precision cutting sawing machine and ordinary double-end cutting sawing machine. Among them, CNC precision cutting sawing machine has the advantages of high processing speed, high efficiency and high precision. The......

CNC Double Head Miter cutting saw.

14 Sep, 2020CNC double-ended precision saw is a kind of double-ended saw, which is developed by adding numerical control system on the basis of precision saw.??It has the following advantages:1, imported numerical control system, digitally controlled cutting length, accurate size.2. The servo motor drives the head to move left and right through the imported ball screw, and the repetitive positioning accuracy is high.3, a series of data can be input to optimize the length at the same time to realize contin......

45 Degree cutting center for aluminum doors and windows

14 Sep, 2020The advantages and characteristics of the intelligent sawing and machining center are "three highs" and "three lows"Three high:● High profile utilization characteristics:The sawing processing center basically realizes cutting without material head (only the blade width). Because the traditional double-headed saw is manual feeding, it must leave a 5-10mm left, and it is controlled by the workers themselves. The use of CNC manipulator for feeding can completely avoid the waste of profiles due to ......

Knowledge: Door & Window Making Machine

About Multi Head Drilling Machine

Aug 23, 2021About Multi Head Drilling Machine This machine adopts 6 set drilling head, each head adopts three-axis drill pack for......

Advantages of aluminium double head cutting saw

Jul 29, 2021Advantages of aluminium double head cutting saw Advantages of aluminium double head cutting saw 1.The double-head ......

How to choose an aluminum cutting saw?

Jun 04, 2021How to choose an aluminum cutting saw? Aluminum profile cutting saw is the main machinery for processing aluminum doo......

What is aluminium crimping machine?

Mar 11, 2021Aluminium Crimping Machine, Aluminium Corner Crimping Machine What is aluminium crimping machine? The angle machi......

What is Double Miter Saw?

Mar 08, 2021Double miter saw for aluminum, Aluminum fabrication machinery Double Miter Saw is a profile cutting tool used in the ......

What is CNC Cutting Center?

Feb 22, 2021CNC Cutting Center, CNC Cutting Machine For Metal & Wood, CNC Profile Cutting & Machining Center CNC stands for Compu......

What is Multi Head Drilling Machine?

Feb 22, 2021Multi Head Drilling Machine, Aluminum Profile Drilling Machine What is Multi Head Drilling Machine? Aluminum prof......

What is aluminum cutting machine

Jan 29, 2021Aluminium cutting machine, Aluminium profile cutting machine What is aluminium cutting machine? Aluminum window an......